Reactivation of spent Activated Carbon

Pertaining to environmental protection, reactivation of spent Activated Carbon and its further re-use is an interesting opportunity.

Activated Carbon is an environmental-friendly and recyclable product, which we reactivate at our two thermal reactivation sites in Germany and Austria whenever possible, offering our customers an attractive reuse option.

For this purpose, we own three rotary kilns which are used to batch-wise reactivation of spent granular or extruded Activated Carbon from diverse application sources which may then be re-used.

Normally, the original adsorption capacity of the carbons can be almost fully restored, hence the process is a sustainable environment-friendly and cost-saving alternative to disposal and/or fresh carbon.

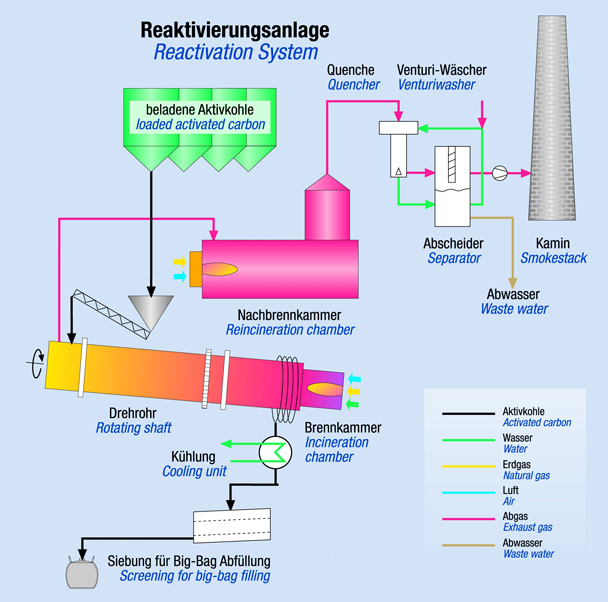

During the process of thermal reactivation, spent Activated Carbon passes through several stages of temperature in a rotary kiln, reaching more than 1000 °C in the last zone.

During the process of thermal reactivation, spent Activated Carbon passes through several stages of temperature in a rotary kiln, reaching more than 1000 °C in the last zone.

After desorption and pollutant pyrolysis, the now again un-loaded Activated Carbon is re-activated by steam. The pollutants released by the reactivation process are destroyed at high temperatures of up to 1200 °C in a downstream incinerator stage followed by flue gas cleanup.

Optimum process control tuned to the specific requirements and the different Activated Carbon grades ensures the production of a high-quality reactivate.

The performance of the reactivation process is monitored by ongoing quality control of the reactivated product.

The performance of the reactivation process is monitored by ongoing quality control of the reactivated product.

At our Landeck site in Austria or in cooperation with certified partners, we can also offer incineration of spent carbon material which cannot be reactivated. Such material is e.g. used in the production process of calcium carbide. This closes the circuit and contributes to environmental protection.

As we always focus on quality and environmental care, our reactivation facilities are licensed under the German Air Pollution Control Act [BimSchG] and operated in strict compliance with the permit requirements.

For clients interested in reactivation, we offer three different ways of taking advantage of this service:

Clients not interested in having their spent Activated Carbon re-activated and sent back to them just deliver us the spent Activated Carbon and get fresh carbon in turn. We re-activate the spent carbon for sale to other customers.

Clients not interested in having their spent Activated Carbon re-activated and sent back to them just deliver us the spent Activated Carbon and get fresh carbon in turn. We re-activate the spent carbon for sale to other customers.- Upon request of client, we offer a strictly batch-wise reactivation, which means that the client gets back his own spent and re-Activated Carbon (the process-related loss of material filled up with fresh carbon), without having this material mixed with others.

- Similar Activated Carbons with equal specification are reactivated pool-wise and made available to other clients for new applications.